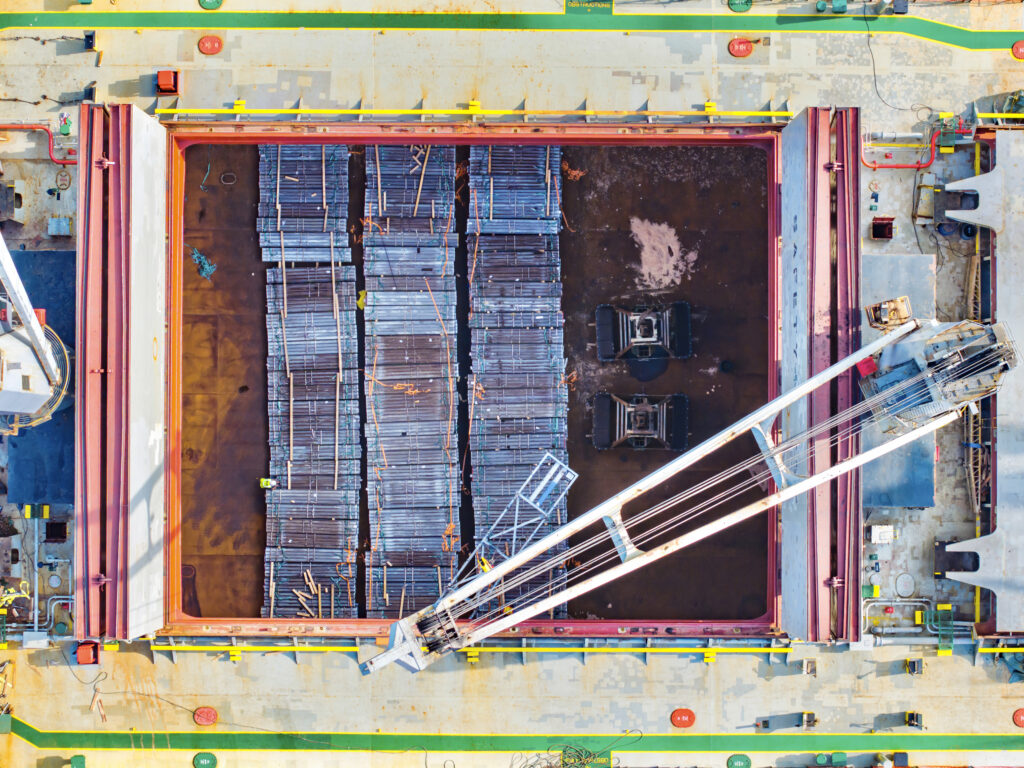

Coordinating the movement of 37.6k metric tons of bundled solar steel structures from India to the U.S.A., was a true test of precision logistics. The challenge intensified as this was not a one-time shipment, the total cargo was distributed across 12 full vessels over a 10-month period, with shipments arriving back-to-back and demanding fast, flawless execution.

From the outset, the complexity lay not only in the scale, but in the detail: each bundle had to be segregated by project and color, with any damaged pieces identified and set aside without interrupting vessel discharge operations. Managing this at port level meant balancing high-volume throughput with meticulous tracking, all while building relationships from scratch with stevedores and local port stakeholders.

In the first vessel’s discharge, limited prior connections with the stevedores posed operational friction. Our team quickly pivoted, engaging directly with every link of the supply chain, from terminal operators to trucking partners, and establishing strong collaboration protocols. These relationships became the foundation for a streamlined process that reduced bottlenecks, minimized errors, and improved cargo flow.

One breakthrough solution was the rapid implementation of a custom in-house inventory management system. This software enabled us to track every bundle in real time, generate accurate packing lists, and perfectly match port-loaded cargo with the trucks dispatched daily to the inland destination.

With the full support of our network partners, who promptly addressed our concerns, acted within tight timelines, and even reduced certain costs, we achieved a level of efficiency that delighted our client. The result was not just the safe delivery of thousands of tons of solar infrastructure, but a proven operational model that could be replicated for future large-scale projects.

At Racing Cargo, we see challenges as opportunities to innovate, strengthen partnerships, and deliver beyond expectations.